Skin customization

Here are all kinds of skins that excite you

Appearance

Various surface treatment methods present a variety of beautiful appearances

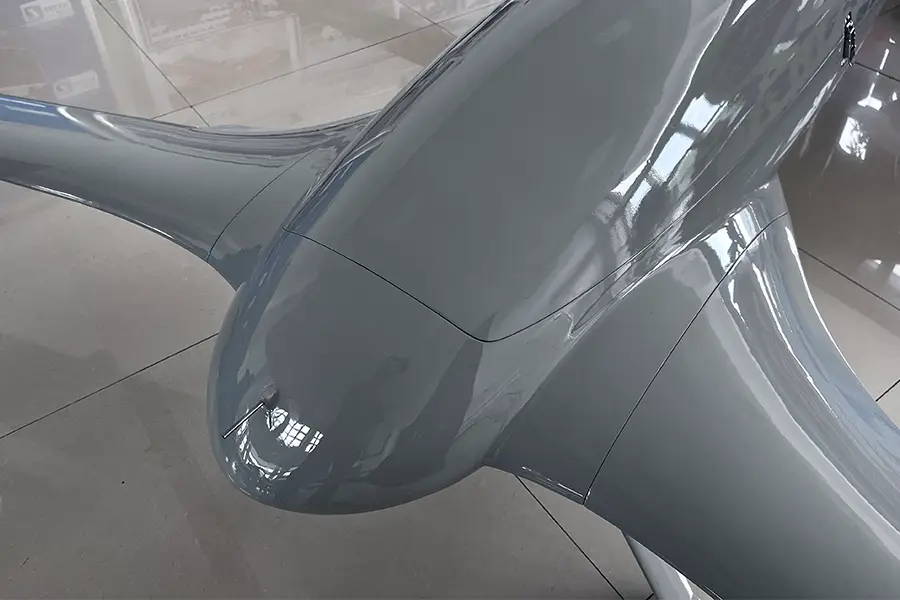

Polish lacquer

Polish lacquer not only protects the skin but also gives it a shiny appearance, making it easier to clean and less prone to getting dirty. However, it increases the weight of the drone

Matte paint

Matte paint is mainly composed of varnish, mixed with an appropriate amount of matting agent and auxiliary materials. Due to different amounts of matting agent, the glossiness of the paint film also varies. The gloss of the matte paint film is soft, uniform, smooth, and resistant to temperature, water, acid, and alkali

Not painted

Usually, the original appearance of the fiber layer is retained, which can reduce the weight of the drone

Fibre material

Different working conditions use different fiber materials, which exhibit different strengths and weights

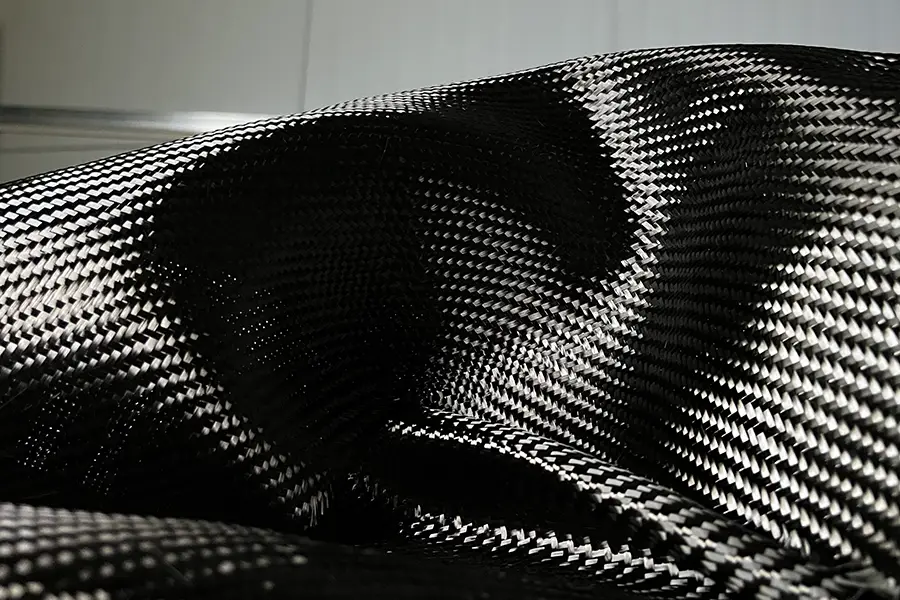

Carbon fiber cloth

High strength, low density, thin thickness, basically without increasing the self weight and cross-sectional size of the reinforced components. High durability, as it does not rust, it is very suitable for use in high acid, alkali, salt, and atmospheric corrosive environments.

Fiberglass

Glass fiber has higher temperature resistance, non flammability, corrosion resistance, good insulation and sound insulation, high tensile strength, and good electrical insulation than organic fiber. But it is brittle and has poor wear resistance. Fiberglass is used to manufacture reinforced plastics or rubber, and as a reinforcing material, it has the following characteristics

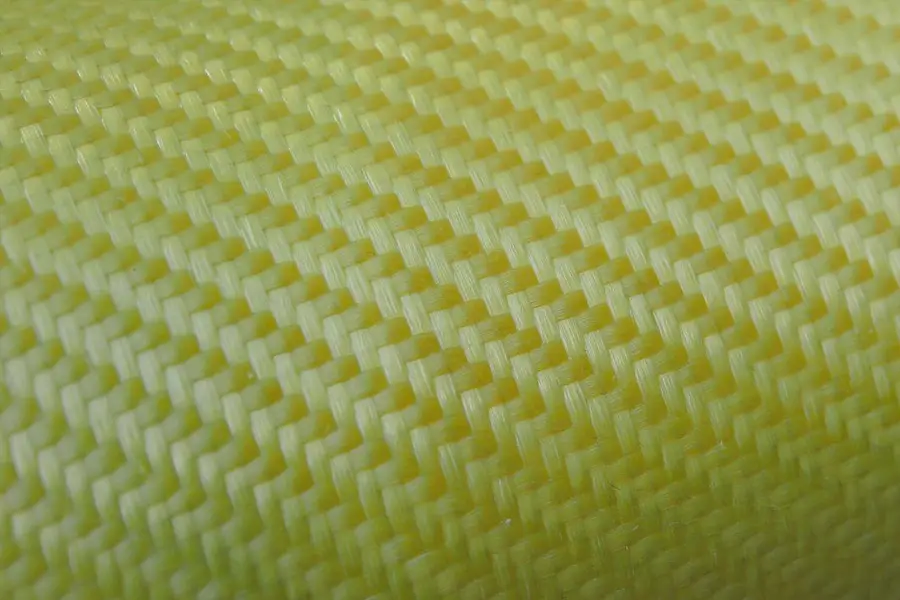

Kevlar fiber

Thermal stability, Kevlar brand fibers are very stable in thermal tests (TGA), and there is no significant weight loss until 600 ℃;Low corrosiveness, Kevlar brand fiber test pieces with high content exhibit lower corrosiveness than semi metallic sheets;Wear resistance, compared to brake pads made of asbestos fiber, shows very low wear resistance when Kevlar brand fibers are well loosened.

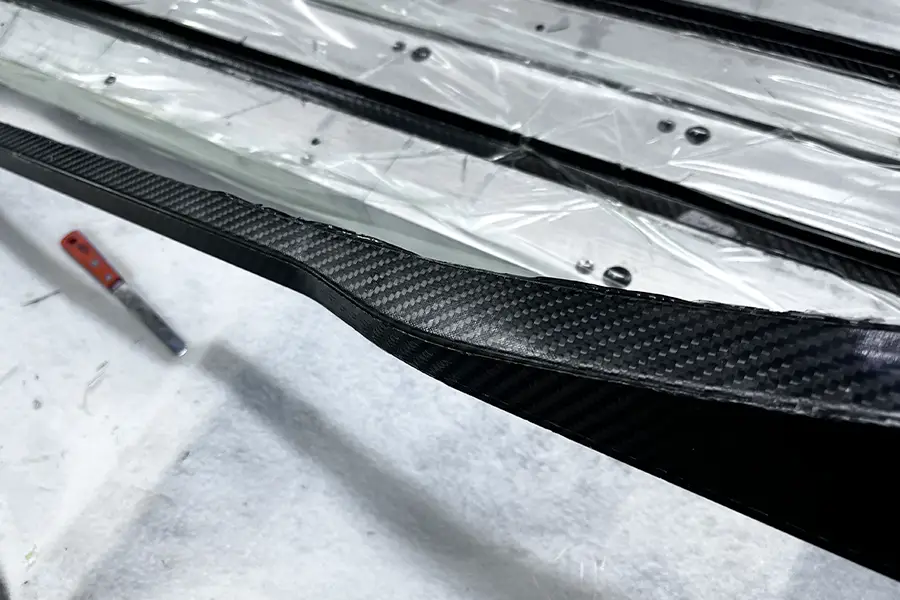

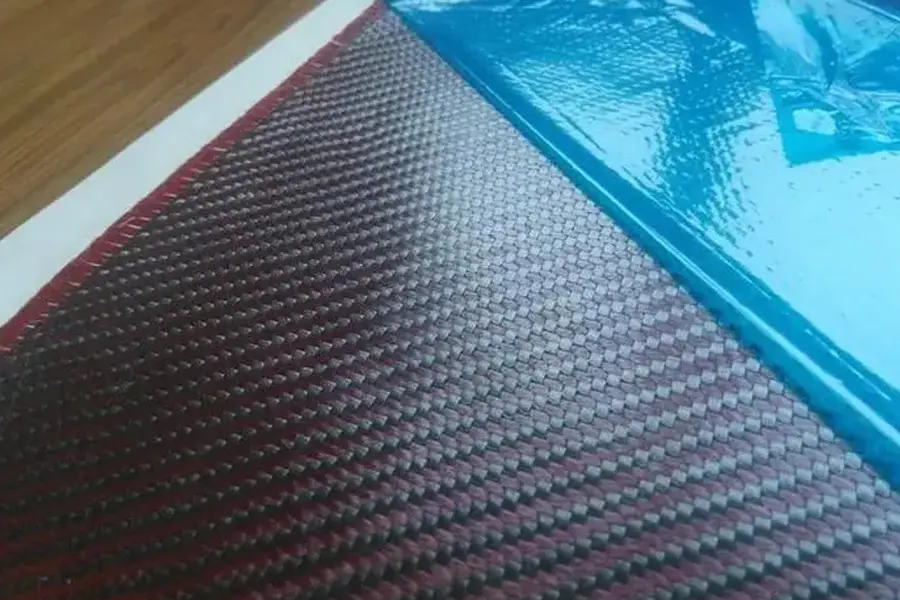

Carbon fiber pre impregnated cloth

Pre impregnated materials are intermediate materials in the manufacturing of composite materials and their components, forming the basic unit of composite materials. The uniformity and stability of their quality are important links to ensure the quality and reliability of composite materials and their components

Core material

Core material laid between carbon cloth to provide support

Foam plastic

The foam core is made of foam plastics. Most commonly used are polyurethane foam, polystyrene foam and phenolic foam. The most commonly used product of load-bearing sandwich structure is rigid polyurethane foam, a newly developed foam core called composite foam