Introducing the Metal Molds

A mold that can be used multiple times and has a small margin of error

Detailed introduction

Strength

These materials can withstand significant pressure and friction, and have a long service life

High-precision

Capable of high-precision machining and able to meet the machining requirements of complex parts

Cost

The cost is higher than other molds

Design

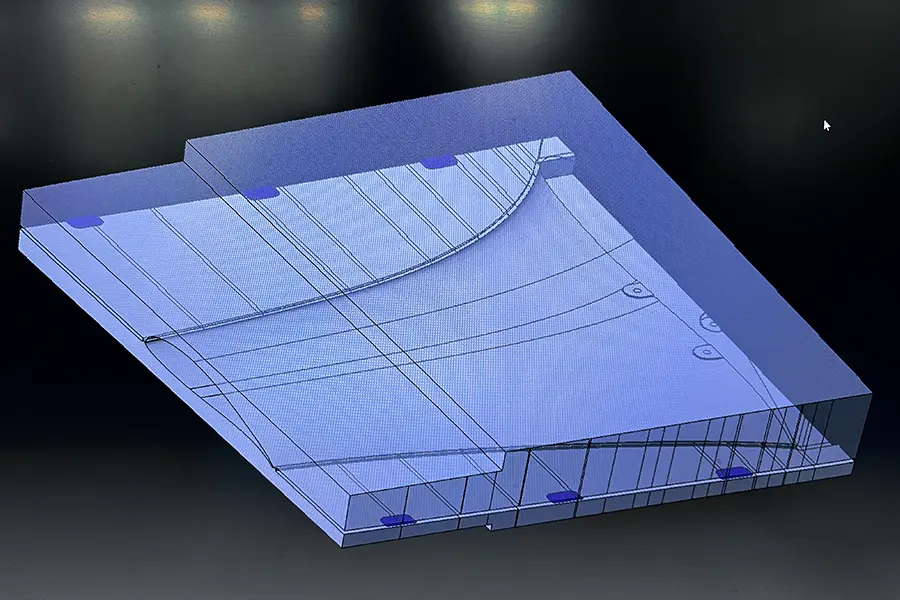

The first step in making metal molds is to design the parts and molds. The designer must first determine the shape, size, material, and other functional requirements of the part. The designer then creates a 3D model that guides the actual production process. This model will also include special features, such as channels and injection ports, for the production of injection molds.

Machining

Upload the model to the machining center for production. The machining center uses digital technology to cut the required mold parts very accurately. Making a single mold requires a very high degree of precision and expertise, as we must guarantee that all molds must be the same precision before using the mold to process.

Assembling

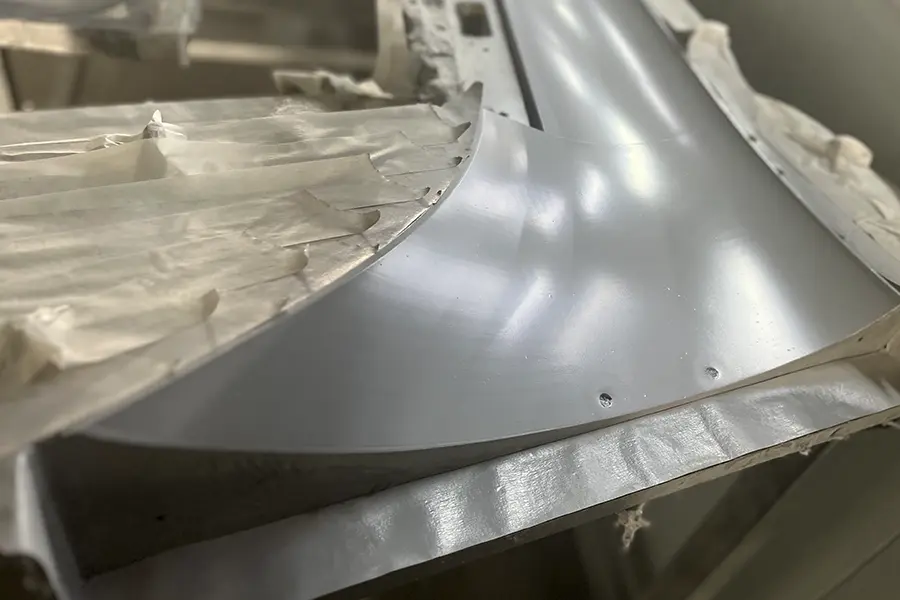

After the mold is finished, it needs to be assembled. In this process, mold details must be carefully analyzed and assembled part by part. After the assembly is completed, the mold must be measured to ensure that the accuracy meets the requirements.

Put to use

After careful inspection of the mold, it is finally applied to production. The molding effect of the product needs to be rechecked, and if there are defects, the mold needs to be adjusted again

About metal molds

The processing adaptability of metal molds is strong, and they can adapt to the manufacturing of various shapes and sizes of components. The finished products produced by metal mold manufacturing have high quality, and the processing can ensure high forming accuracy and stability.

In short, metal molds have the advantages of high precision, long service life, good stability, and strong processing adaptability, and have become essential tools in various industrial fields. With the continuous advancement of technology and process innovation, metal molds will have a broader application prospect in the future.